Introduction

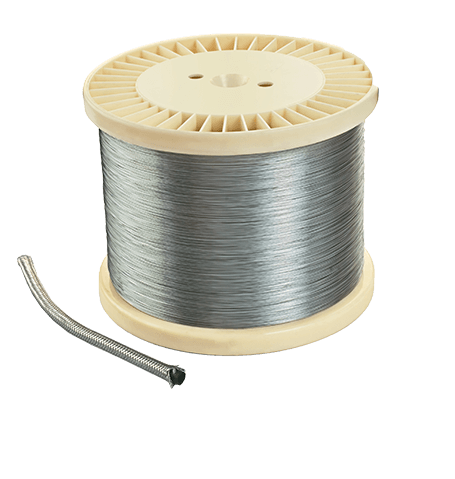

KEl’s Stainless Steel Wire for Cold Heading is made by special heat treatment, copper-bearing austenitic steel302CHQ, 304HQ, normal 304 and 430 are also used for cold heading fasteners.

Special Characteristics

Excellent corrosion resistance and mechanical strength and is the most suitable material for bolts,screws and other fasteners and has a marked work hardening characteristics.

Supply Conditions

All KEI wires are coated to ensure smooth heading operations Condition. Cold drawn and Annealed, Cold drawn, Annealed and skin pass or as per customer requirement with very fine tolerance.

Mechanical Properties

| Annealed Finish | Light Drawn | ||||||

|---|---|---|---|---|---|---|---|

| Type | Grade | Tensile Strength N/mm2 (Kgf/mm2) | Elongation (%) | Reduction of area rate (%) | Tensile Strength N/mm2 (Kgf/mm2) | Elongation (%) | Reduction of area rate (%) |

| Austenite | AISI 304/316 | 490-740 (60-75) | 40 over | 70 over | 650-800 (66-81) | 25 | 65 |

| AISI 302HQ | 440-90 (45-60) | 40 over | 70 over | 460-640 (47-65) | 25 | 65 | |

| Ferrite | AISI 430 | 40-55 | 20 over | 65 over | 460-640 (47-65) | 10 | 60 |

Diameter Tolerances And Ovality

| Dia (Mm) | Tolerances(Mm) | Ovality(Mm) |

|---|---|---|

| 0.80-1.90 | +0.00-0.02 | 0.010 |

| 2.00-3.50 | +0.00-0.03 | 0.015 |

| 3.51-8.00 | +0.00-0.04 | 0.020 |

| In coils on formers placed on pallets. | ||

Classification

| Type | Grade | Diameter (mm) | Surface Finish |

|---|---|---|---|

| Austenite | AISI304 AISI302HQ | 0.80-8.00 | Bright De-coated wire or sterate coated |

| AISI316 | 0.80-8.00 | ||

| Ferrite | AISI430 | 0.80-8.00 | Bright De-coated wire or sterate coated |

| Packing specifications | |||

Subscribe Newsletter

Subscribe Newsletter